Njengoqoqosho, kulula ukuyilungisa kunye nokucwangcisa imathiriyeli yokwakha, ikhonkrithi ineempawu ezibalaseleyo zomzimba kunye nezomatshini, ukuqina, ukusebenza kunye nokuthembeka, kwaye isetyenziswa ngokubanzi kulwakhiwo loluntu. Nangona kunjalo, akunakuphepheka ukuba kuphela i-samente, isanti, ilitye kunye namanzi zixutywe, ngoko umphumo wekhonkrithi eqhelekileyo, ithoni yayo yokubonakala ayithandeki kangako, kwaye kulula ukuyigalela kunye nokubuyisela ityuwa. Ngoko ke, umgangatho wekhonkrithi wangaphakathi uvame ukugqunywa ngekhaphethi, i-vinyl okanye i-tile kunye nezinye izinto zokugubungela, kwaye udonga lusetyenziswa kakhulu njengomgangatho wokuhlobisa, i-tile okanye i-mortar yokugqiba, iphepha lodonga.

Namhlanje, inkqubo yokuhombisa umphezulu wodaka lwekhonkrithi iye yaba yenye yeendlela ezihlonitshwa kakhulu zobugcisa bekhonkrithi kuMntla Merika naseOstreliya. Oku kwavela kwiminyaka yee-1950 inkqubo yekhonkrithi yokunyathela emgangathweni (istampedconcrete), oko kukuthi, umphezulu wekhonkrithi entsha utshizwe nge-hardener yombala, ngokusebenzisa i-molds ye-pattern kunye nee-arhente zokukhulula, umphezulu wekhonkrithi ukulinganisa ipateni yokuthungwa kweefom zendalo, ezifana negranite, i-marble, i-SLATE, ingqalutye okanye i-texture texture. Ukuhlangabezana neemfuno zabantu kwiziphumo zokuhombisa izinto zendalo. Le teknoloji ayifanelekanga kuphela kwikhonkrithi entsha, kodwa ilungele ukulungiswa kwendawo ekhoyo yekhonkrithi, efana nentendelezo yendlu, imijelo yegadi, i-driveways, amadama okuqubha ukuya kumhlaba wokuthenga kunye neehotele. Impembelelo yokuhombisa le ebizwa ngokuba yi-art mortar surface layer ine-fidelity yendalo kunye nokukodwa, enokuthi ihlaziye imbonakalo ebuthuntu yekhonkrithi, kodwa iphinde isete ukuhombisa kunye nokusebenza kwenye, nto leyo ayinayo kuphela uqoqosho, ukuqina kunye nokusebenza kwekhonkrithi, kodwa kunye ne-organically idibanisa i-aesthetics kunye nobuchule.

Ngokwahlukileyo koko, iminyaka elindelekileyo yokuphila kwee-substrates zekhonkrithi eqhelekileyo ingaphezulu lee kwezo zezixhobo zokugquma ezisetyenziswa ngokuqhelekileyo, ngelixa ikhaphethi kunye nemathiriyeli ye-vinyl ithanda ukukrazula, intonga kunye nokuguga, kunye nokungcoliswa kwamanzi, kwaye ezi zixhobo zomgangatho kufuneka zitshintshwe rhoqo emva kweminyaka embalwa. Umphezulu wodaka wobugcisa womelele njengekhonkrithi, ucocekile kwaye kulula ukuwugcina, kwaye isiphumo sawo sokuhombisa sinokudityaniswa ngokulula kunye nesitayile soyilo esijikelezileyo kwaye sidityaniswe kwindawo engqongileyo. Ngokungafaniyo nekhaphethi okanye i-vinyl veneer materials, i-art surface mortar awonakaliswa lula ngokukrazula, ukubambelela, ukukrazula okanye ukuphuphuma kwamanzi; Akukho misonto okanye iintanda zokufihla uthuli okanye izinto ezimele zithintele umzimba, kwaye kulula ukuzicoca okanye ukugungxulwa ngokulungiswa okuncinci. Xa kuthelekiswa nenkqubo yokuprinta iipateni kumphezulu omtsha wekhonkrithi, inkqubo yodaka lomphezulu wobugcisa ilula, ikhawuleza kwaye inoqoqosho ngakumbi.

ADHESi-emulsion powder efumanekayo kwakhona - icandelo eliphambili lodaka lomphezulu wobugcisa

Ngokwahlukileyo kudaka lwesiqhelo lokutyabeka lwesiqhelo, udaka lwekhonkrithi yobugcisa bokugquma kufuneka luqulathe i-polymer ye-organic ukongeza kwi-pigments, kwaye olu daka yinto esiyibiza ngokuba yi-polymer modified dry mix mortar. I-polymer-modified cement-based surface material yenziwe ngesamente, iaggregate, pigment, ADHES. i-emulsion powder efumanekayo kwakhona kunye nezinye izongezo, kwaye zinokuhlangabezana neemfuno ezahlukeneyo zokusebenza zokwakheka kunye nokuqina kakuhle ngokuhlengahlengisa ifomula.

Izixhobo zomphezulu ezisekwe kwisamente ezilungisiweyo zePolymer zaziswa kubunjineli bomgangatho worhwebo ngeminyaka yoo-1980, ekuqaleni njengezinto zokulungisa umaleko obhityileyo womphezulu wekhonkrithi. Udaka lwanamhlanje lwezobugcisa alukwazi ukusetyenziswa kuphela kumhlobiso womgangatho wezihlandlo ezahlukahlukeneyo, kodwa zilungele ukuhlobisa iindonga. Udaka lomphezulu oluguquliweyo lwepolymer lunokubekwa lubhityile kakhulu, ubukhulu balo bunokuba lolona bungakanani besuntswana lesanti, okanye ubukhulu bamashumi eemilimitha ngaphandle kokukhathazeka malunga nokuxobuka, ukuqhekeka, okona kubaluleke kakhulu, umaleko womphezulu oguqulwe wepolymer unokumelana okunamandla netyuwa, izinto ezinobundlongondlongo, ukukhanya kwe-ultraviolet, iimeko zemozulu ezirhabaxa kunye nokunxitywa kwezithuthi okubangelwa bubuchule bomonakalo.

Udaka lomphezulu wobugcisa lune-ADHESi-emulsion powder efumanekayo kwakhona, Ukubambelela kwayo okuphezulu kunokuqinisekisa ibhondi eqinile phakathi kwezinto ezingaphezulu kunye ne-concrete substrate, kwaye inike udaka lobugcisa obuhle bokugoba amandla kunye nokuguquguquka, okunokumelana kangcono nemithwalo eguquguqukayo ngaphandle kokulimala. Ngaphezu koko, umaleko womphezulu wodaka unokufunxa ngcono uxinzelelo lwangaphakathi oluveliswa lutshintsho lobushushu obuphakathi kunye nokufuma ngaphakathi kwesixhobo kunye nojongano, ukuze kuthintelwe ukuqhekeka kunye nokuqhekeka kodaka lomgangatho ongaphezulu. Ukuba ADHESi-emulsion powder efumanekayo kwakhonakunye neempawu ze-hydrophobic zisetyenzisiweyo, ukufunxwa kwamanzi kwi-mortar mortar kungancitshiswa kakhulu, ngaloo ndlela kuncitshiswe ukungena kweetyuwa ezinobungozi kwisiphumo sokuhombisa udaka lomphezulu kunye nomonakalo wokuqina kodaka.

I-ADHES iguqulelwe ukwakhiwa kodaka lomphezulu wobugcisa

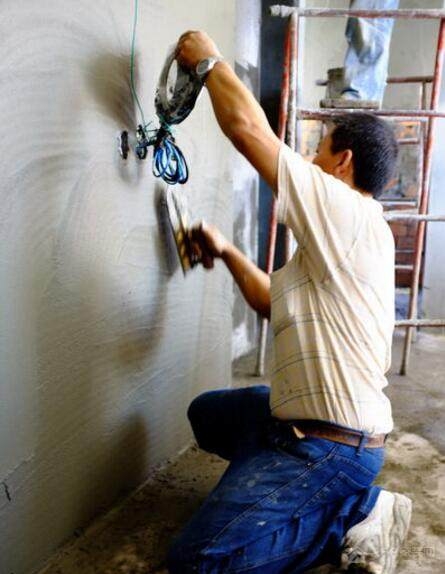

Udaka lobugcisa olusetyenziswa kwimiphezulu yekhonkrithi esele lukhona kufuneka kuqala luthotywe igrisi kwaye lucocwe. Ukuba kukho ezinye izinto ezingaphezulu kwikhonkrithi ezifana neengubo, i-tile mosaics, i-adhesives, njl., ezi zixhobo kufuneka zisuswe ngeendlela zoomatshini ukuqinisekisa ukuba umphezulu wodaka lobugcisa unokubotshwa ngoomatshini / ngokwekhemikhali ngokuqinileyo kwi-substrate yekhonkrithi. Kwinxalenye yokuqhekeka, kufuneka ilungiswe kwangaphambili, kwaye indawo yokudibanisa ekhoyo kufuneka igcinwe. Emva konyango olusisiseko, umphezulu wodaka lobugcisa unokwakhiwa ngokwamanyathelo afanelekileyo.

Ubugcisaudakainkqubo yokwanyisa umphezulu

Umphezulu onempembelelo efanayo yokuhlobisa njengenkqubo yekhonkrithi yendabuko inokufumaneka ngokusebenzisa inkqubo yokufaka i-embossing. Okokuqala, sebenzisa i-scraper okanye i-trowel ukugqoka i-interface layer ye-polymer modified sement material njengento encinci kunokwenzeka, kwaye ubukhulu bubukhulu becala lesanti. Xa i-putty layer isemanzi, udaka lobugcisa obunombala obumalunga ne-10mm ubukhulu busasazwa nge-marker harrow, i-harrow marks isuswa nge-trowel, kwaye ipateni ye-textured ishicilelwe kunye nembonakaliso efanayo ne-concrete ye-embossed yendabuko. Emva kokuba umphezulu womile kwaye uqinile, i-sealant ene-pigment ifafazwa. Ulwelo olutywiniweyo luya kuzisa umbala kwiindawo ezisezantsi ukuvelisa isitayela samandulo. Nje ukuba amaqhuma ome ngokwaneleyo ukuba ahambe, iidyasi ezimbini ze-acrylic transparent finish sealant zingafakwa phezu kwazo. Ukusetyenziswa kwangaphandle okucetyiswayo kwe-anti-slip cover sealant, emva kokuba i-sealant yokuqala yomile, kwaye emva koko ukwakhiwa kwe-anti-slip coating, ngokuqhelekileyo umphezulu unokucinezelwa kwiiyure ezingama-24 emva kokugcinwa, iiyure ezingama-72 zinokuvulwa kwi-traffic.

Inkqubo yokwaleka komphezulu wodaka lobugcisa

Ukutyeba malunga ne-1.5-3 mm, ilungele ukusetyenziswa kwangaphakathi nangaphandle. Ukwakhiwa kwe-putty layer enemibala ifana nalapha ngasentla. Emva kokuba umaleko weputty womile, iteyiphu yephepha incamatheliswa ngokungakhethiyo kumaleko weputty ukwenza ipateni, okanye iphethini enomngxuma wephepha efana nelitye, isitena, ithayile ibekwe, emva koko udaka lobugcisa olunombala lufafazwe kumaleko weputty ngecompressor yomoya kunye nompu wokutshiza wefunnel, kunye nodaka olunombala olutshizwe kwiputty luyagudiswa okanye loyiswe ngamandla ngetropi. Oku kudala umphezulu wokuhombisa onemibala, osicaba, okanye okwaziyo ukutyibilika. Ukuze udale umphumo wendalo kunye nokwenyani, indawo eyomileyo yomdaka inokusulwa ngobumnene ngesipontshi esinombala onamabala. Emva kokuba indawo enkulu yokucima igqityiwe, phinda lo mkhuba ungentla ukuze unzulu umbala okanye uqinise umbala wendawo. Imibala emininzi inokukhethwa ngokweemfuno, emva kokuba umbala ugxininiswe kwaye uqiniswe, vumela umphezulu wome ngokufanelekileyo, ususe i-tape okanye iphethini engenanto yephepha, ucoce umphezulu, kwaye usebenzise i-sealant efanelekileyo.

Ubugcisaudakaumphezulu umaleko self-leveling inkqubo yokudaya

Kweli nqanaba, i-self-leveling art mortar surface isetyenziswa ikakhulu ngaphakathi, ngokuqhelekileyo ngokusebenzisa ukudaya ukwenza iipateni, ezihlala zisetyenziswa kwiindawo zorhwebo ezifana nomgangatho wemoto yomboniso, ihotele yehotele kunye neendawo zokuthenga, iipaki zemixholo, kodwa zifanelekile kwizakhiwo zeofisi, indawo yokuhlala yokufudumeza. Ubukhulu boyilo lwepolymer ehlengahlengisiweyo yomgangatho we-self-leveling art surface layer imalunga ne-10mm. Njengomgangatho wokwakha udaka lomgangatho wokuzenzela, ubuncinci i-agent ezimbini ze-styrene acrylic emulsion interface ziqala ukusetyenziswa ukuvala i-pores kwi-substrate yekhonkrithi, ukunciphisa izinga lokufunxa kwamanzi, kunye nokwandisa ukunamathela phakathi kodaka oluzimeleyo kunye ne-concrete substrate. Emva koko, i-self-leveling mortar surface layers isasazwa kwaye amaqamza omoya asuswe ngokusebenzisa i-roller yokukhupha umoya. Xa i-self-leveling mortar iye yaqina ukuya kwinqanaba elithile, izixhobo ezifanelekileyo zingasetyenziselwa ukukrola okanye ukusika ipateni ngokwendlela yokuyila kunye nokucinga kuyo, ukwenzela ukuba umphumo wokuhombisa ongenakufumaneka kunye nezinye izinto zokuhombisa ezifana neekhaphethi kunye neethayile azikwazi ukufunyanwa, kwaye kuqoqosho ngakumbi. Iipatheni, uyilo lobugcisa kunye neelogo zenkampani zinokusetyenziswa kwiindawo ezizilinganisayo, ngamanye amaxesha zidityaniswe nokuqhekeka kwekhonkrithi ye-substrate okanye ukufihla ubugcisa beendawo ezibangela iintanda kumphezulu. Umbala unokufumaneka ngokongezwa kwangaphambili kwee-pigmentsudaka lokuzilinganisa oluxutyiweyo olomileyo, kwaye ngokuphindaphindiweyo ngonyango lwasemva kokudaya, ii-colorants ezenziwe ngokukodwa ziyakwazi ukusabela ngokwekhemikhali kunye namacandelo ekalika kumdaka, okhupha kancinane kwaye ulungise umbala kwindawo yomgangatho. Ekugqibeleni, isikhuseli sokutywina sokuvala sisetyenziswa.

Ukugqiba i-sealant kunye nepolisi

Ukugqibezela izitywini kunye nokugqiba linyathelo lokugqibela kuzo zonke iileya zokuhombisa ezisetyenziselwa ukutywina, ukunxiba kunye nemiphezulu yodaka yobugcisa obungangeni manzi, ukusuka kwizitywini eziphezulu zemizi-mveliso ukuze zisetyenziswe ngaphandle ukuya kwiipolisha zokusetyenziswa ngaphakathi. Ukukhetha i-sealant okanye i-wax ehambelana nombala wokugqitywa kodaka kunokuphucula ithoni kwaye yongeze i-luster, kunye neengubo ezicacileyo zingabonisa incasa ye-antique kunye ne-luster okanye yenze imibala yemichiza ibonise i-mottled traces. Ngokuxhomekeke kumthamo wetrafikhi kwisicelo somgangatho, i-sealant okanye i-wax inokuphinda isetyenziswe ngamaxesha athile, kodwa ukugcinwa kunokwenziwa ngokungaqhelekanga njenge-wax yomgangatho. Ukuze ugweme umonakalo kwi-art mortar surface kunye nokugqoka kwezithuthi, ukuba ukuhamba kwezithuthi emhlabeni kuphezulu, i-agent ekhuselayo yokutywina ingasetyenziswa ngamaxesha amaninzi. Ukugcinwa rhoqo kunokugcina kakuhle umphumo wokuhlobisa umgangatho ophezulu, kunye nokwandisa kakhulu ubomi bayo benkonzo.

Iindleko kunye nokunciphisa

Ixabiso eliqhelekileyo lobugcisa bekhonkrithiudakaumphezulu udla ngokuba yi-1/3-1/2 ephezulu kunento yebhloko yendalo efana ne-SLATE okanye igranite. Izinto zomgangatho oqinileyo ezifana nethayile, igraniti okanye ikhonkrithi yokuhombisa ayinakuba nomtsalane kubathengi abakhetha izinto ezithambileyo ezifana neekhaphethi okanye izinto zevinyl ezithambileyo. Iziphene zisenokubakho kubushushu obuphantsi kweenyawo, ukusasazeka kwesandi kunye nokuba nokwenzeka kokuphuka kwezinto, okanye ukhuseleko lomntwana onokukhasa okanye awe phantsi. Abantu abaninzi bazimisele ukubeka imibhobho emincinci kwimigangatho enzima okanye emide kwiindlela zokuhamba kunye neendawo zokongeza ubuhle, kodwa ukukhethwa kwezi zinto kufuneka kufakwe kwibhajethi.

Njengenye yeendlela ezisebenzayo zokuhombisa ikhonkrithi, udaka lomphezulu wobugcisa lulula, lunoqoqosho kwaye luhlala ixesha elide, kulula ukulugcina, kwaye lolona phawu lubalaseleyo lobuhle kunye nobuchule.

Ixesha lokuposa: Feb-23-2024